-

PRODUCTS

-

APPLICATIONS

- design support

-

TECHNOLOGY

-

Quality & Reliability

- Quality Policy

- Quality System

- Qualification Summary

- Reliability Report

- Reliability Stress Model

- Ongoing Reliability Monitoring

- Reliability Testing Facilities

- Failure Analysis Laboratory

- Certifications

- Management Of Hazardous Substances

- WHERE TO BUY

- Investor Relations

-

ABOUT US

- Company

- Citizenship

- EHS Management

- Partners

- Investors

- News & Events

- Career

- Suzhou Fab video

- Zhuhai Fab video

ABOUT INNOSCIENCE

Innoscience Releases Two Low-Voltage GaN Motor Drive Solutions, Infusing Robots and Drones with Superior Power

11Sep 2025 News

Motor Drive applications demand high performance and compact size, but traditional silicon-based (Si) power devices have reached their performance ceiling. Innoscience, the leading global manufacturer of gallium nitride (GaN) power semiconductors, has launched two high-performance, low-voltage motor drive solutions: INNDMD48V25A1 (discrete solution) and INNDMD48V22A1 (integrated solution). These solutions offer revolutionary breakthroughs for low-voltage motor applications such as robots, drones, and power tools.

Solution Overview

Both new products from Innoscience utilize a 48V~60V input and support continuous peak output phase currents of 25A/22A, perfectly suited for 1kW-class motor drive requirements.

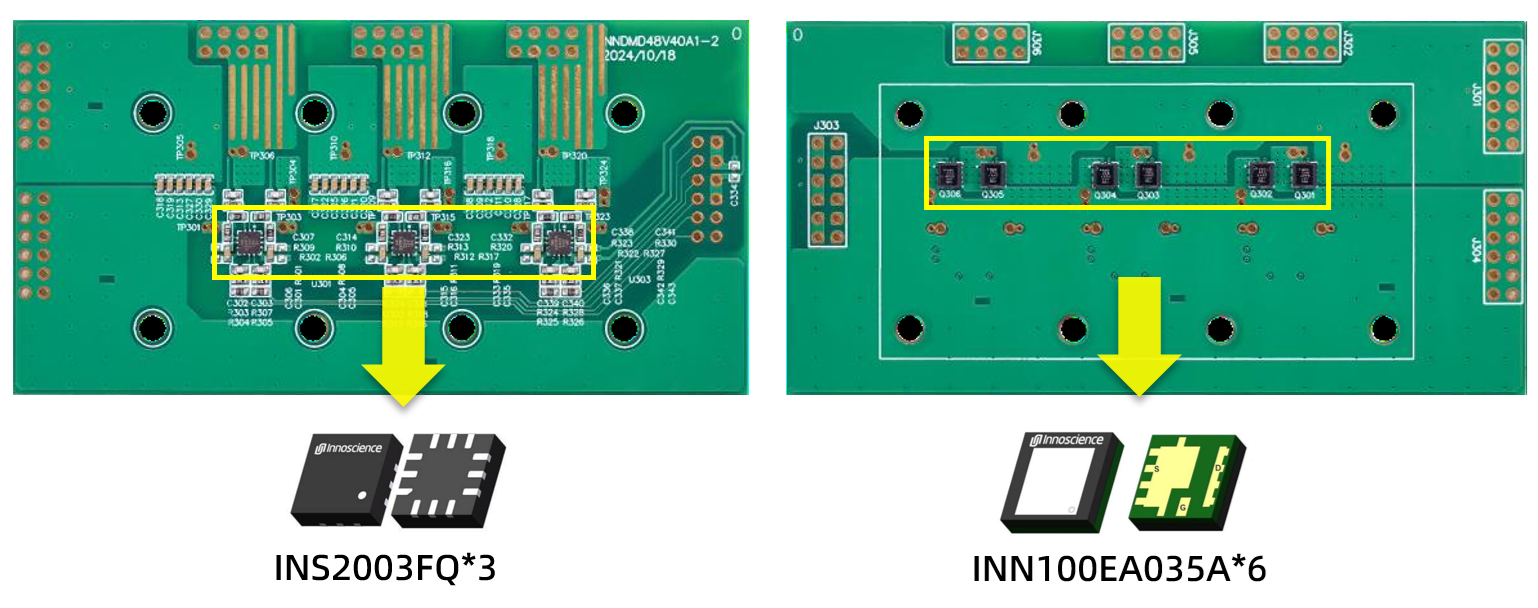

INNDMD48V25A1 (discrete solution) utilizes six INN100EA035A discrete devices and three INS2003FQ dedicated driver ICs, this solution maximizes flexibility for a discrete solution.

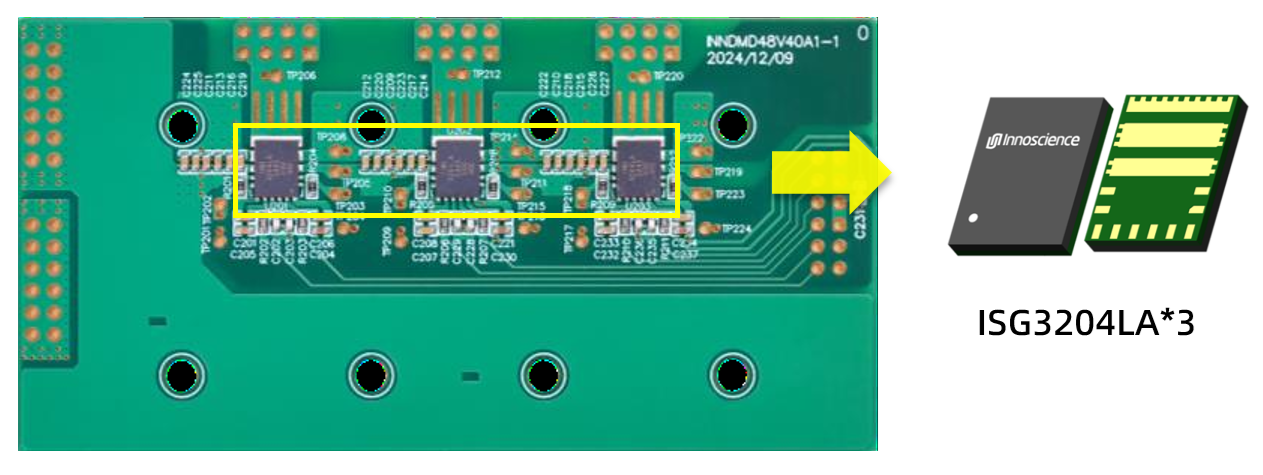

INNDMD48V22A1 (integrated solution) uses three ISG3204LA half-bridge GaN chips (with built-in drivers), offering high integration and a simpler layout.

These two GaN solutions from Innoscience have major advantages which surpass Silicon solutions:

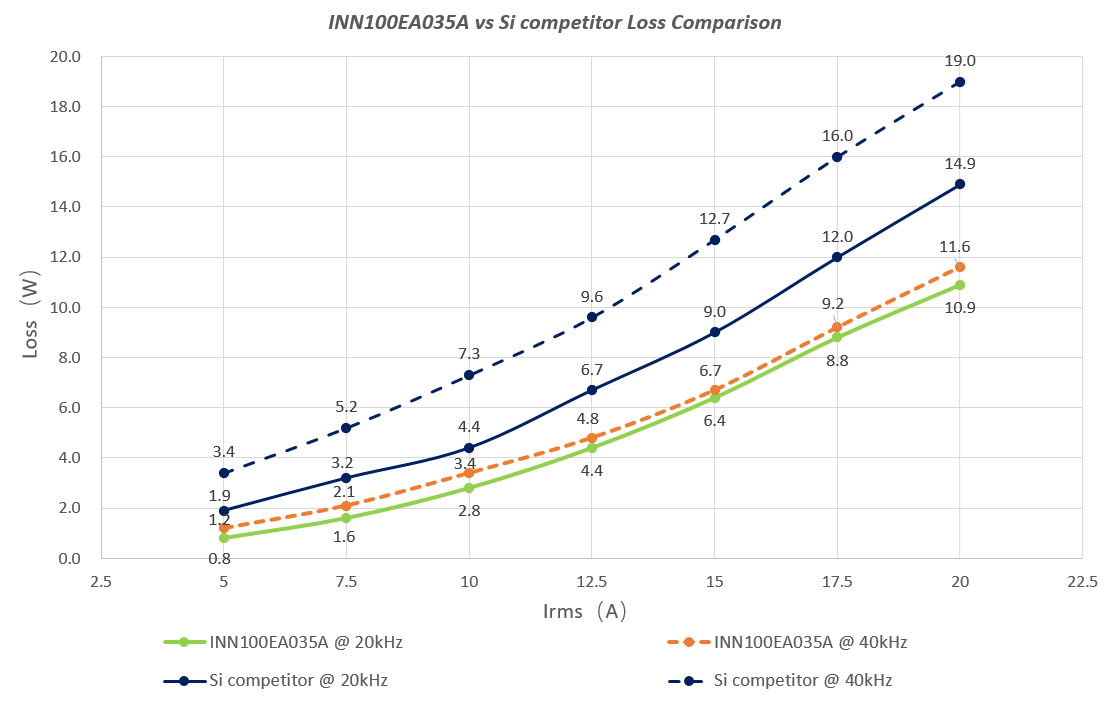

- Significantly reduced losses and significantly improved energy efficiency

- High efficiency even up to 40kHz switching frequency and 20A phase current

- The discrete solution (INN100EA035A) achieves total losses of 11.6W, compared to 19W for the benchmark Si solution (39% reduction)

Figure 1: Discrete GaN vs. Si solution loss comparison

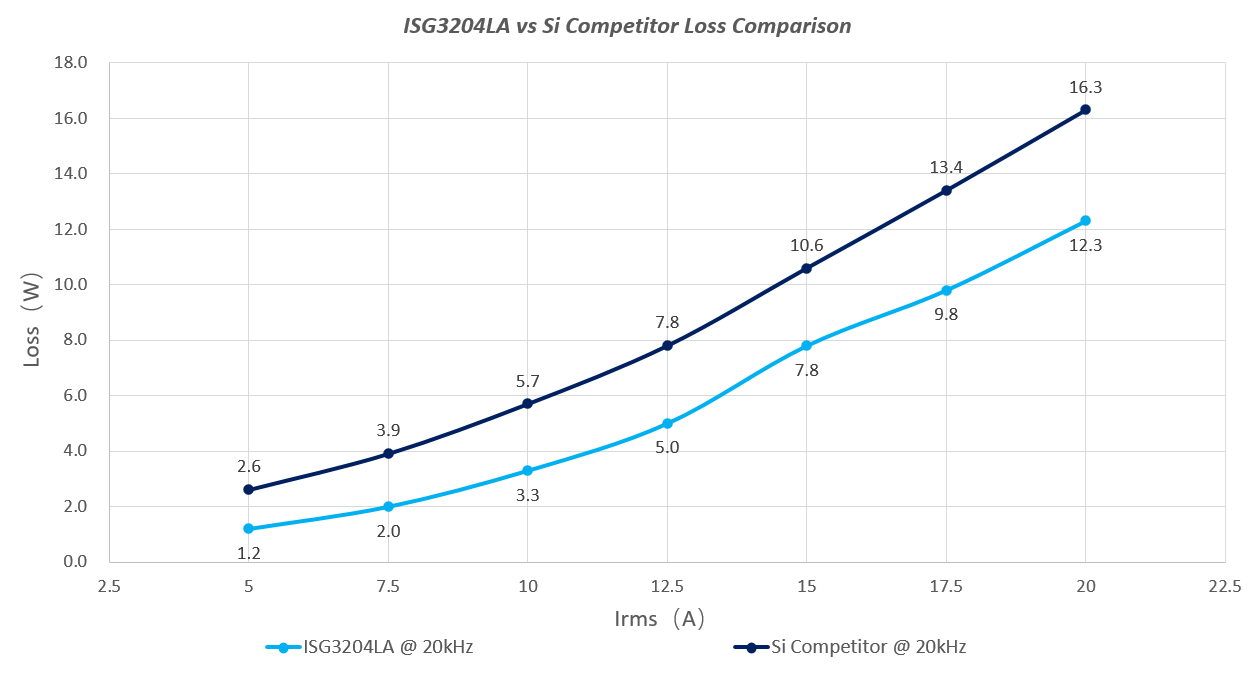

The total power loss of the package-on-package solution (ISG3204LA) is 12.3W, while the benchmark Si solution is 16.3W, a reduction of 24.5%.

Figure 2: Loss comparison of integrated GaN solution vs. Si solution

Excellent high-frequency performance facilitates high power density (miniaturization). GaN devices offer fast switching speeds, reducing dead time to as little as 100ns. When the switching frequency is increased from 20kHz to 40kHz, the GaN system loss in the INS2003FQ + INN100EA035A discrete device solution increases by only 0.7W, while the Si solution increases by 4.1W, resulting in an 83% reduction in incremental GaN losses. The increased frequency results in a temperature rise of only 10°C, leaving room for further frequency increases and smaller inductor and capacitor sizes.

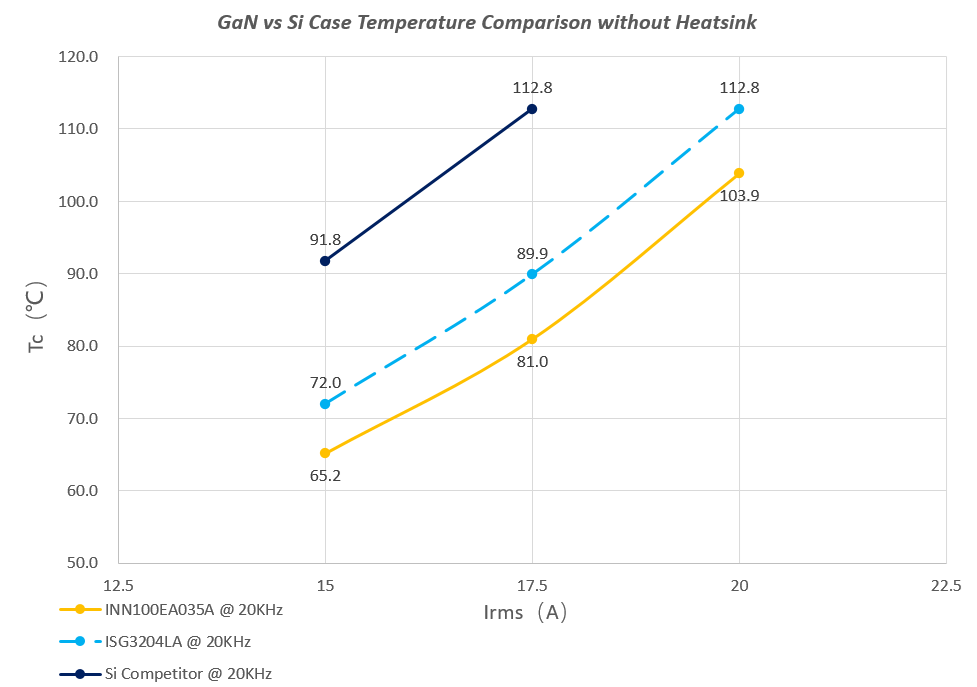

Figure 3: GaN vs. Si temperature rise comparison

Excellent thermal performance, more reliable systems. Under the same cooling conditions, GaN device temperatures are over 23°C lower than Si solutions. At phase currents below 18A, the on-package GaN solution eliminates the need for a heat sink, significantly reducing system size.

Higher current output capability and power density. The discrete GaN solution offers a 3.5A increase in maximum RMS output current over the Si solution. Under the same temperature rise conditions, it can support higher load currents and easily achieve higher power density.

Application Scenarios

- Robot servo drive

- Drone electronic control system

- Magnetic levitation transmission production line

- Low-voltage servo integrated machine

- Garden tool/electric two-wheeler controller

Friendly design accelerates market adoption

The INNDMD48V25A1 (discrete solution) provides a reference for optimized layout, significantly reducing the impact of parasitic parameters. The INNDMD48V22A1 (on-package solution) leverages the integrated drive circuitry of on-package GaN devices, resulting in a simpler layout, smaller PCB area, and shorter development cycles.

Innoscience's newly released low-voltage motor drive solution offers high efficiency, low temperature rise, high frequency, and compact size, providing a powerful power core for next-generation high-performance motor systems. Whether pursuing a discrete solution for ultimate performance or a package-in-package solution for ease of integration, this solution helps customers easily upgrade their products and achieve competitive differentiation.

Contact us now at MARCOM@innoscience.com to obtain a complete demo manual, test data, and technical support, and bring the power of GaN chips to your motor drive designs!

- PRODUCTS

- HV GaN HEMT LV GaN HEMT VGaN SolidGaN Driver IC Work With Us

- APPLICATIONS

- Consumer electronics Renewable energy and industrial Automotive electronics Data center

- DESIGN SUPPORT

- Application Notes Device Model Demo Board Technical And Training Documents

- Quality & Reliability

- Quality Policy Quality System Qualification Summary Reliability Report Reliability Stress Model Ongoing Reliability Monitoring Reliability Testing Facilities Failure Analysis Laboratory Certifications Management Of Hazardous Substances

- WHERE TO BUY

- Where To Buy Authorized Distributors

©2021 Innoscience ALL RIGHTS RESERVED 粤ICP备18107445号

Career / CONTACT US

English

English

简体

简体